Automating The Order Fulfillment Process

Van Meter distributes electrical parts to Iowa’s contractor, commercial, OEM, systems integrators, and

energy markets. Their 300,000 sq. ft. Distribution Center in Cedar Rapids, IA acts as the primary hub for picking and packing orders for their 12 satellite locations and servicing over-the-counter customers. Due to rapid growth, Van Meter’s lines per year grew 20%, peaking at over 1.08 million. Continued growth and delivery of quality customer service depended on a solution which better utilized existing space and increased order picking efficiency and accuracy.

The Solution

As part of a larger warehouse automation project, Van Meter rerouted orders via conveyor into new picking zones featuring 18 Vertical Lift Modules from Kardex Remstar. The Kardex Shuttles are arranged into 4 work zones each integrated with pick-to-light technology and Kardex Power Pick System software to enable batch picking within each zone.

Van Meter’s transformation from a small Iowan electrical distributor carving a name for themselves in a post-depression economy, to a 100% employee-owned company known around the region for their exceptional customer service is nothing short of inspiring.

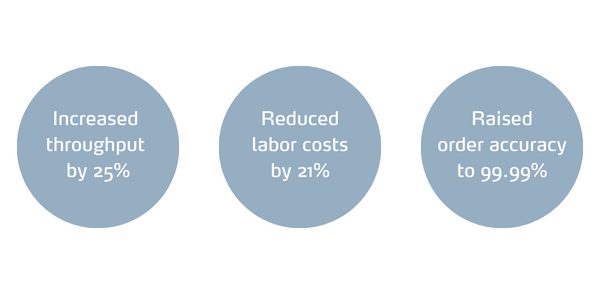

Now fulfilling orders using a warehouse-wide pick and pass fulfillment strategy, Van Meter has doubled picking throughput, reduced labor requirements by 21%, and increased accuracy to an astounding 99.99%.

| 18 Kardex Shuttles organized into 4 picking zones | |

| Kardex Power Pick System | |

|

Dual Tray Delivery |

.jpg)