ASRS Helps Find the Right Fit for Parts Distributor

Bristol Hose delivers fitting and connector group (FCG) parts, such as hoses, fittings, adapters, and quick couplers, to municipalities, utility companies, and manufacturers in the Greater Chicago Area. Their Melrose Park facility doubles as a primary distribution center and storefront for over-the-counter sales. A combination of increasing order volume and rising on-hand inventory had Bristol Hose constantly reshuffling bins and rearranging inventory, decreasing efficiency overall.

The Solution

When Bristol Hose acquired a new 65,000 ft2 facility they consolidated 85% of their inventory into just three Vertical Lift Modules (VLMs), with two workers picking and preparing orders. The VLMs are positioned to facilitate efficient material flow for both order picking and replenishment. The remaining inventory, including fast-moving parts and bulk items, is stored in flow racking and static shelving.

Tony Tuminaro, Director of Operations at Bristol Hose said, “With the VLMs our existing employees can pick faster and are more efficient so we don’t need to hire more people.”

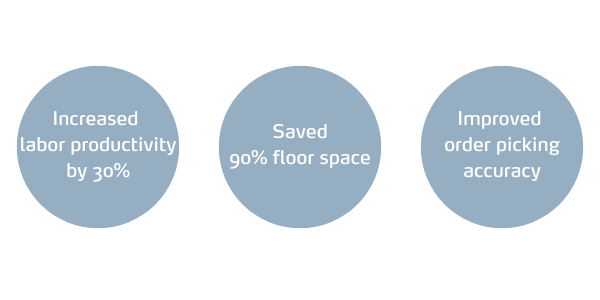

With their new warehouse equipped with three Vertical Lift Module Kardex Shuttles with Kardex Power Pick System inventory management, Bristol Hose has increased labor productivity by 30%, saved 90% floor space, and improved order picking accuracy.

| 3 Vertical Lift Module Kardex Shuttles | |

| Kardex Power Pick System | |

|

Pick-to-light Display |

.jpg)