Zone Picking with ASRS Supports Manufacturing Warehouse

With a reputation for groundbreaking tractor and utility vehicles Kubota’s parts promise is what keeps customers coming back. Kubota’s 60,000 square foot part center in Markham, Ontario has steadily grown to over 78,000 SKUs. The facility utilizes a pick and pass strategy with six Horizontal Carousel Module Kardex Horizontal Carousels and four Vertical Lift Module Kardex Shuttles with Kardex Power Pick System inventory management software.

“Our parts promise to our customers presents an operational challenge as we have to inventory parts that are only picked once a year. To meet our parts guarantee we must be able to find it,” says Doug Ward, Logistics Manager, “and the system we had in place made that difficult.”

Previously, Kubota inventoried parts in two zones: a mezzanine shelving area for manual picking and a hi-bay shelving area using man-up trucks to access parts. The productivity rates and ergonomic risks prompted Kubota to look for a more efficient automated solution.

The Solution

Kubota now uses a pick and pass strategy with three picking zones, two of which are automated for maximum efficiency. Six Kardex Horizontal Carousels manage the fast-moving SKUs; four Kardex Shuttles manage the medium moving SKUs, and the slower moving SKUs are stored in hi-bay shelving.

The complete system was purchased and implemented in phases. In the first phase, Kubota purchased six Kardex Horizontal Carousels to replace a three-story mezzanine in coordination with a building relocation. The Kardex Horizontal Carousels provided ergonomic picking and a dramatic increase in productivity.

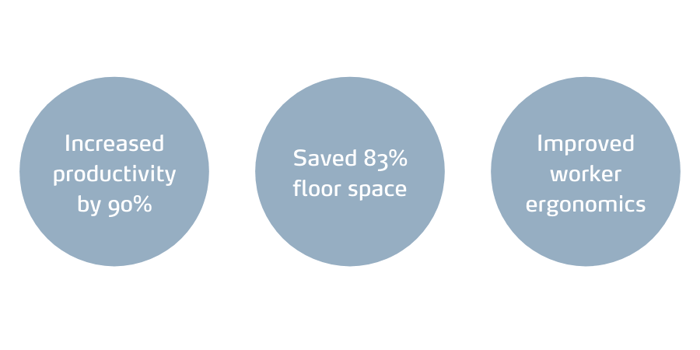

In the second phase, Kubota added another work zone using four Kardex Shuttles. “We were out of space and were considering an expansion,” says Ward, “The Kardex Shuttles allowed us to free up floorspace and avoid a costly building expansion.”

Productivity Increases

In the mezzanine zone workers were picking an average of 20 lines per hour. “We couldn’t throw any more bodies into the mezzanine zone without people tripping over each other. With parts sales growing we needed to pick faster,” said Ward. Now, one person working in the horizontal carousel zone picks an average of 225 lines per hour while bagging and tagging. “We were able to increase our picking productivity by over 90% and only need one worker to manage the carousel zone,” said Ward.

Replacing some of the high-bay shelving with Kardex Shuttles in phase two also resulted in a productivity increase. With only one worker in the Kardex Shuttle zone and eliminating travel and search time in the hi-bay shelving, picking productivity has increased by 50%.

| 6 Kardex Horizontal Carousels | |

| 4 Kardex Shuttles | |

| Kardex Power Pick System |

.jpg)