Efficient Order Consolidation for Automotive Parts Distributor

Headquartered in Germany, Hella Distribution GmbH, supplies customers worldwide with automotive parts and accessories for original equipment as well as the aftermarket sector. To guarantee fast and accurate daily deliveries, extend warehouse capacity and create an efficient and ergonomic order consolidation process, they opted for an automated Vertical Buffer Module Kardex Compact Buffer.

With long-standing experience in the automotive industry, Hella ships over 2,000 orders globally every day. To keep up with rising customer demand, Hella needed to automate their manual processes of loading cartons onto pallets and storing them until needed. Furthermore, they needed to optimize their processes to increase ergonomics, reduce sort and search times, and minimize walking distances.

The Solution

A six-meter tall Kardex Compact Buffer works as a consolidation buffer for customer orders awaiting shipment. Conveyor technology automatically transports various sized cartons, previously prepared for shipment, to the Kardex Compact Buffer, where they are scanned and stored.

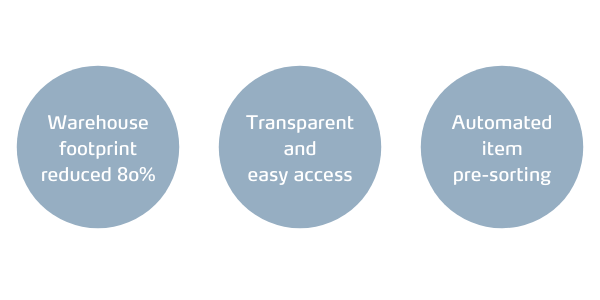

Once a truck has arrived, a complete list of relevant orders is easily created. Pre-sorted by size and weight, the orders are delivered in a specific order to two Kardex Compact Buffer access openings. Employees scan the cartons and manually move them from the Kardex Compact Buffer onto a pallet for final shipment.

”With the Kardex Compact Buffer, we were able to save 80% of storage space and no longer face any capacity restrictions,“ says Raphael Heimann, Project Manager Intralogistics, Hella Distribution.

|

1 Kardex Compact Buffer with three access openings |

|

|

Kardex JMIF |

|

Conveyor connection |

.jpg)