Automated Warehouse Solution Supports Precision Manufacturer

Park Industries in St. Cloud, MN manufactures stone working machines that cut, polish and edge stone into slabs for commercial and home use. Driven partly by the granite/quartz countertop trend, as well as entering the metal cutting industry by introducing CNC plasma machines; Park Industries has experienced rapid growth over the last five years - putting a squeeze on the warehouse – literally.

Previously their warehouse utilized a manual paper picking process with associates pushing picking carts up and down aisles of shelving collecting parts. “It was very messy – the aisles were so crowded with parts it was difficult to maneuver the carts down the aisles, and when the aisle was clear - finding parts was tough,” said Elaine Ohman, Inventory Control Manager, “We were bursting at the seams.”

Knowing they needed to improve efficiencies to support their growth, Park Industries turned to automation. They needed a solution: 1 – to utilize vertical height to create additional capacity; 2 – to deliver parts to the worker automatically to eliminate wasted walk time; 3 – that could be easily expanded to handle future growth; 4 – to integrate and communicate with their current ERP; 5 – to provide easy access to data for reporting; and 6 – that was user friendly. They were looking for a total solution – a combination of hardware and software – to improve warehouse fulfillment operations.

The Solution

The Solution

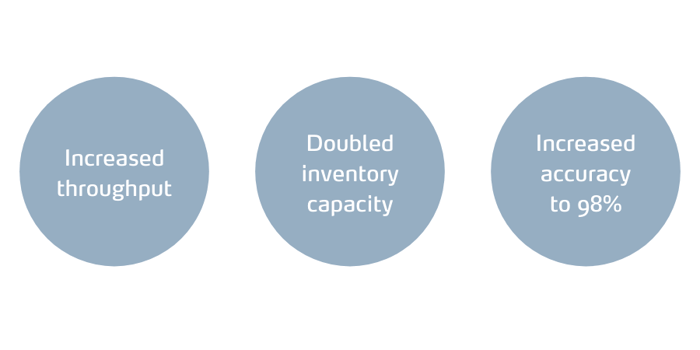

The warehouse today has four Kardex Shuttles with pick to light technology integrated Kardex Power Pick System inventory management software. They installed the automated material handling solution in stages - starting with two Kardex Shuttles, adding a third two years later, and a fourth just recently. Within the same footprint and using the same labor requirements, the warehouse now fulfills twice the number of orders and has doubled inventory capacity.

Park Industries boasting over 5,000+ unique machine parts in stock with a next day delivery guarantee. This level of commitment requires a highly organized and efficient warehouse. “It’s critical we manage all parts efficiently – fast, medium and slow moving SKUs – when a customer needs it, we have to find it,” said Mark Shankey, Warehouse Supervisor and Training “and it needs to be in clean, usable, working condition.”

Cycle counting is a focus in the warehouse. “Previously our inventory accuracy was about 90%,” said Shankey, “now with the Kardex Shuttles and a cycle counting process in place we are at 98% - meaning we know what we have and more importantly where it is.” The warehouse cycle counts every day, counting roughly 15% of their inventory each month to avoid a consuming yearend inventory count.

| 4 Kardex Shuttles | |

| Kardex Power Pick System | |

| Pick to light technology |

.jpg)