Controlled Environment Storage with Direct Access from Lab

Merck is a leading science and technology company in the pharmaceutical and chemical industry. Merck is committed to changing the world through science and technology. Employing 50,000 people in 66 countries, Merck develops and supplies specialized products in the healthcare field.

A newly constructed research building required three zones to supply, prepare, manage, and

store pharmaceutical research substances under special storage conditions. Laboratory staff needed the ability to access the cool and deep-freeze warehouse from a room temperature area.

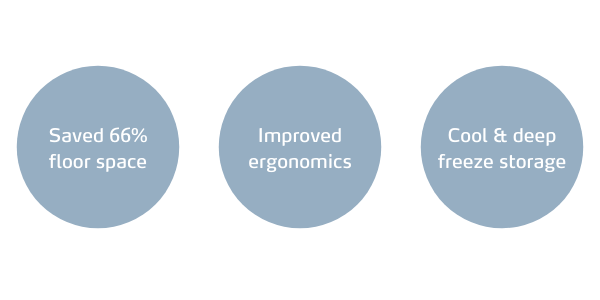

Using 3 Vertical Lift Module Kardex Shuttles created a customized controlled-environment storage solution with a hatch unit in front of the Kardex Shuttle access opening. The solution has a built in redundancy system to secure the controlled storage conditions.

The Solution

Merck implemented a customized solution including three standard Kardex Shuttle, modified for cold conditions. Metal dividers within the trays create ideal storage locations and a pick to light laser pointer identify the exact product to pick.

A refrigeration unit cools the interior of the Kardex Shuttles and a redundant cooling unit with redundant sensors takes over. The air is dehumidified by a drying device to prevent humidity from condensing and icing in the Kardex Shuttle. Additionally, the units are clad in insultation panels.

Laboratory staff can now access the stored goods in the air-conditioned units directly from a room temperature laboratory.

|

3 Kardex Shuttles with thermally decoupled auto tray extraction |

|

|

Kardex Power Pick System Laser pointer |

|

3 cooling systems (including redundancy system) Drying technology |

.jpg)